doi: 10.56294/evk202350

ORIGINAL

H2S Hydrogrn Sulfide risk factors, conditions and work environment in processes in the oil industry in Argentina

H2S Ácido Sulfhídrico factores de riesgo, condiciones y medio ambiente de trabajo en procesos en la industria petrolera en Argentina

Agostina Constansa Rodriguez1, Hernan Carlos Hoyos1

1Universidad Siglo 21, Licenciatura en Higiene Seguridad y Medio Ambiente del Trabajo. Argentina.

Cite as: Rodriguez AC, Hoyos HC. H2S Hydrogrn Sulfide risk factors, conditions and work environment in processes in the oil industry in Argentina. eVitroKhem. 2023; 2:50. https://doi.org/10.56294/evk202350

Submitted: 22-07-2022 Revised: 22-10-2022 Accepted: 19-12-2022 Published: 01-01-2023

Editor: Prof.

Dr. Javier Gonzalez-Argote ![]()

ABSTRACT

The purpose of this Final Graduation Project is to investigate exploring the different work processes, to visualize the occupational exposure to H2S hydrogen sulfide of a worker in the oil field, their atmospheric environment, working conditions, work environments, dangers and risks, in order to guarantee compliance with the permissible limits in current occupational health and safety regulations. In the oil industry, H2S is present in the atmosphere of all processes, various plants, batteries and locations because it is part of oil and gas, high concentrations can cause damage to health, or even death by suffocation and high contamination to the environment. For this, surveys were carried out obtaining data and analyzing the information of the workers of the different sectors, the majority have little knowledge of the exposure to H2S, the potentiality and severity of this gas, the work they do is dangerous.

Keywords: H2S (Hydrogen Sulfide, Hydrogen Sulfide, Hydrogen Sulfide Gas, Hydrogen Sulfide); Concentrations; Repeated or Prolonged Exposure; Working Conditions; Working Environment; Oil; Damage to Health; Death.

RESUMEN

El propósito de este Trabajo Final de Graduación es investigar explorando los diferentes procesos de trabajo, para visualizar la exposición laboral al H2S sulfuro de hidrógeno de un trabajador en el ámbito petrolero, su ambiente atmosférico, condiciones laborales, entornos de trabajo, peligros y riesgos, con el fin de garantizar el cumplimiento de los límites permisibles en la normativa vigente de seguridad y salud ocupacional. En la industria petrolera el H2S se encuentra presente en la atmosfera de todos los procesos diversas plantas, batería y locaciones pues es parte de petróleo y gas, las altas concentraciones puede causar daño para la salud, o incluso hasta la muerte por asfixia y contaminaciones elevadas al medio ambiente. Para ello se realizó encuestas obteniendo datos y analizando la información de los trabajadores de los diferentes sectores, la mayoría tiene poco conocimiento de la exposición al H2S, la potencialidad y severidad que tiene este gas, el trabajo que realizan es peligroso.

Palabras clave: H2S (Sulfuro de Hidrógeno; Ácido Sulfhídrico; Gas Sulfhídrico; Hidrógeno Sulfurado); Concentración Permisible; Exposición Repetida o Prolongada; Condiciones de Trabajo; Entorno de Trabajo; Petróleo; Daños a la Salud; Muerte.

INTRODUCTION

The oil industry represents one of the most dynamic, complex, and risky sectors in the industrial field,(1,2) where working conditions require rigorous safety, occupational health, and environmental planning.(3,4,5) Within this context, this research focuses on the analysis of the risks associated with hydrogen sulfide gas (H₂S) exposure in three companies operating in different oilfields in the province of Chubut, Argentina: YPF (Comodoro Rivadavia - Escalante - Trébol oilfields), PAE Pan American Energy (Dragon Hill) and CAPSA (Diadema Argentina).(6,7,8) This research aims not only to identify the hazards faced by workers but also to analyze the level of knowledge, prevention, and training regarding the handling of hazardous chemicals, especially H₂S.(9,10,11)

The methodological design of this study is exploratory, descriptive, and comparative, with a quantitative-qualitative and cross-sectional approach.(12,13,14) Data were collected in the field through surveys, interviews, and the use of specialized measuring instruments, such as calibrated gas detectors, as well as direct observation of procedures in various operational areas. The sample consisted of randomly selected personnel from each of the companies, ensuring representativeness and diversity in functions and tasks.(15,16,17)

Through the analysis of the collected data, significant deficiencies in awareness, training, and the practical application of preventive measures were identified. In many cases, operational staff do not adequately recognize the hazards associated with H₂S, do not have access to the necessary documentation, and do not follow standardized procedures.(18,19,20) This scenario poses significant risks to both the health of workers and the safety of the facilities.(21,22)

This paper aims to make an initial contribution to comprehensive improvement in oilfield risk management, proposing lines of action and recommendations to enhance safety culture and reduce the incidence of adverse events related to hazardous chemical agents.

How does the level of knowledge, training, and application of preventive measures influence exposure to H₂S gas in workers of companies operating in oilfields in the province of Chubut?

Objective

The primary objective of this research is to investigate how the risks associated with H₂S, an extremely toxic, flammable, and corrosive gas naturally present in hydrocarbon extraction and treatment processes, are managed. It also seeks to evaluate the working conditions, the personal protective equipment (PPE) used, the documentary protocols available, and the training of personnel about this hazard.

METHOD

Design

The present investigation has an exploratory scope with the purpose of highlighting the fundamental aspects of a specific problem already studied, descriptive to identify the characteristics of the population and the different processes and places, comparative, 3 (three) companies providing the same service in various fields were purchased.

The type of research is transversal; it was carried out in the field with data collection of the different processes with measuring instruments only once in the 3 (three) companies to be purchased in oilfields: YPF Comodoro Rivadavia - Escalante - Trébol. PAE Pan Amerycan Energy Dragon Hill. CAPSA Diadema Argentina.

The study employs a quantitative-qualitative approach, utilizing numerical data collection and analysis to establish behavioral patterns, causal explanations, and predictions. The design was non-experimental because there was no manipulation of the variables; only the phenomena were observed.

Population and sample

The research was conducted using a comparative population sample of 3 companies that provide services in the locality of Comodoro Rivadavia, Trébol, Escalante Dragon Hill, and Diadema Argentina, including Oilfields YPF, PAE Pan American Energy, and CAPSA. The population data were provided by the safety, health, and environment departments of each company, as well as Chiappori Nicolas, Gamarra Gisella, and Villares Alfonso. A small group of people were randomly selected and contacted personally. The sampling was conducted through a mathematical calculation for qualitative studies with a finite population, ensuring representativeness.

The finite population sample size was calculated using the following formula:

N = Size of the population or universe (120).

Z = Statistical parameter that depends on the confidence level (50 % = 0,674). e = Maximum accepted estimation error (6,00 %).

p = Probability of event success (50,00 %).

q = Probability that the event does not occur (50,00 %).

n = Target sample size (25,15).

Data collection tool

It is used as a tool for data collection and requires consent signed by the respondents and consent signed by the proxy of one of the companies for the use of measuring and photographic equipment in the different areas of work. Individual surveys consist of a consent form and questions with multiple-choice answers, which the respondent must complete. This will be done in person, personally, and from any web browser or mobile device through an invitation link to the Google Forms platform. Before sending and carrying out the surveys, the person was contacted by telephone.

Another tool used in situ was a measuring equipment, a detector of 4 gases: O₂, CO, H₂S, and LEL, model SP-MGT-P SK 0909213, with its respective calibration dated 06-05-2021 and an expiry date of 06-11-2021. It is worth noting that the calibrations of this equipment are performed every 6 months.

Certifications are attached as an Annex. The form is attached as Annex.

Data analysis

The data obtained from the surveys will be tabulated in an Excel spreadsheet and graphically represented as needed. The frequency of occurrence of specific responses is assessed to determine the population's exposure.

Time frame

The present research work was developed in 3 months, starting from the collection of information, carrying out the surveys, analysis of data obtained, and the formulation of conclusions.

RESULTS

The collection of data and information was carried out using a list of questions in person and with a Google form, carrying out all the personnel to be surveyed; with this, we tried to delve into the range of ages working in the oilfields, categories, jobs performed, areas and processes, exposure to H2S and how it affects health, materials, and environment to which they are exposed, associated risk factors, working conditions, and environment.

Requested documentation to be implemented for the different jobs in the companies or sites.

It was also discovered that the people surveyed have little knowledge of this gas, how to recognize it, and how to act when it is present, despite working in an environment where it is constantly present and being aware of the PPE that should be used for tasks involving exposure.

Figure 1. Place of residence

According to the data and information from the surveys, there are personnel working in the oilfields of the city of Comodoro, Rivadavia, Province of Chubut, who are not from the city but who work under a labor regime. For example, they work 25 days and rest for 10 days.

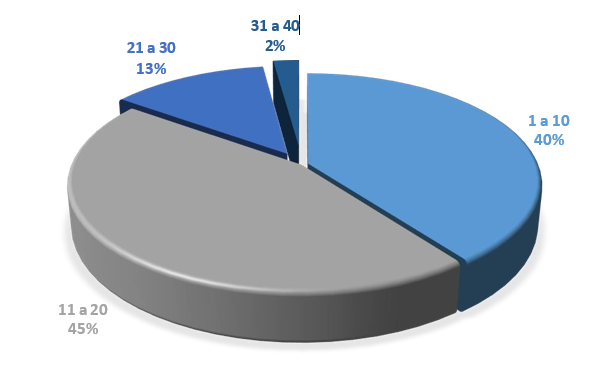

Figure 2. Age ranges

The ages of the staff in the different areas and tasks vary in the 3 (three) companies.

Figure 3. Job Vacancies

Figure 4. 1-2 Operators cleaning and sanitising the facilities

Figure 5. Operator is planing pipe 4 with 750/115 mm angle grinder

Figure 6. 4-5 Confined space welding with scaffolding on cutting tank, south floor

Figure 7. Heavy Equipment Operators: Truck, Hydrocrane, and Crane Operation

Figure 8. Rigger performing production control at the wellhead

Figure 9. Chamber formwork

Figure 10. Two crews working together to change the strobe on the mule head

Figure 11. Probing and excavation for repair of 2" line

Figure 12. Coordination of work with supervisor and crew leader

Figure 13. Supervisors observing concrete setting tasks

Figure 14. A. Sampling at the wellhead B. Separation into test tubes of hydrocarbons extracted from the wellhead, water, and oil

Figure 15. Experiences

Years of experience in the jobs.

Related to the area, types of work, tasks to be performed and work environment.

Details of the services provided at the different sites, divided by category.

Figura 16. Work Area

The items are divided into areas with their respective responsible persons, management and middle management.

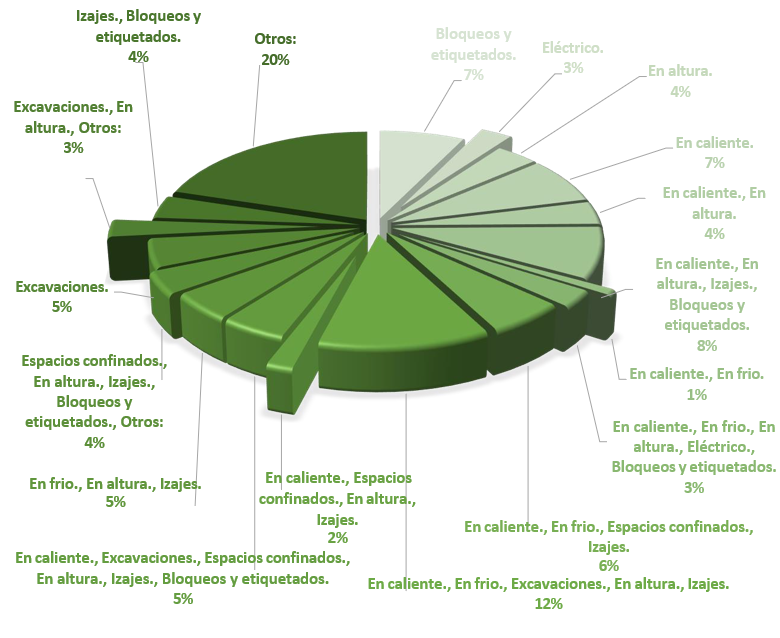

Figure 17. Types of work they do

Different tasks are performed by operating personnel in the oilfield industry.

The guidelines followed by operators for different jobs include taking precautions to ensure the safety of people and facilities, identifying hazards, and assessing risks to determine control measures that prevent accidents—promoting the development of a culture based on safe work practices.

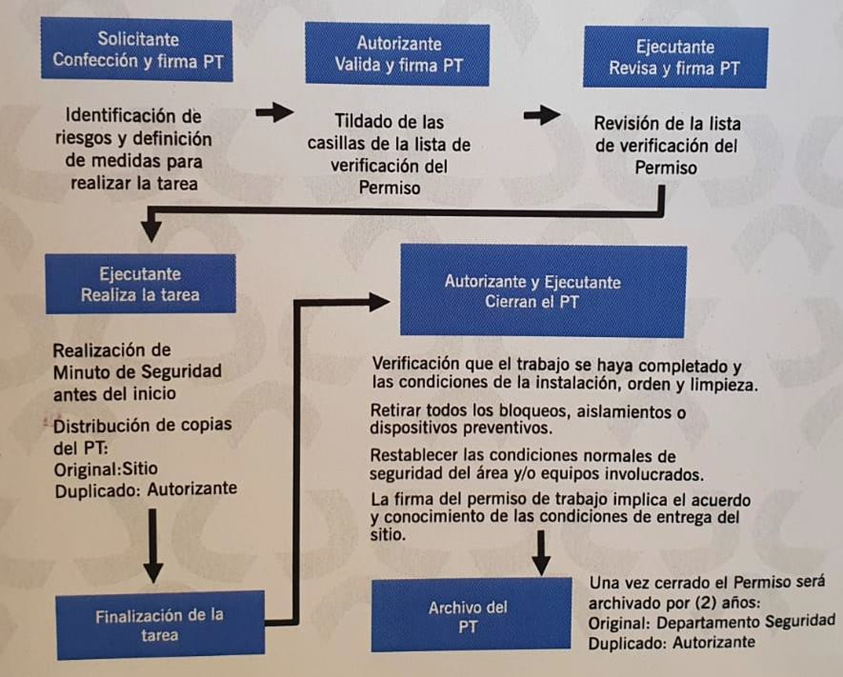

The first step in implementing a permit-to-work system is to identify the jobs, tasks, or operations to which it is applicable. These jobs require the issuance of one or more WPs through a Risk Analysis or a Decision Tree from which each area can draw up its reference list and record it in the Register. It is clarified that these guidelines are neither exhaustive nor limiting and should be taken as a guide to applying for Work Permits.

The Applicant, together with the Authorising Officer, shall be responsible for analyzing the work using the Decision Tree to determine whether a Permit to Work is required.

Flow diagram

Figure 18. Flow diagram

When work is carried out on the premises of another person in charge and, the tasks are non-critical. It will be sufficient to have an ATS or an entry authorization endorsed by what would be the figure of the Authorising Officer if the Work Permit System were applied, for which the work is divided according to the following table:

Process diagram

Figure 19. Process diagram

|

Table 1. Examples and Control Measures for Work |

|||

|

Confined spaces (An enclosed or partially enclosed space that is not designed for human occupancy. It has accesos y salidas limitadas para su ingreso y egreso). |

Example of activities |

· Reservoir tanks, reservoir pools, well chambers, pits and/or sewers, drainage chambers, cisterns. · Crude oil heaters, treaters. · Places where there is a risk of accumulation of gases, vapours or oxygen deficiency. · Excavations/trenches deeper than 1,20m depth. |

|

|

Task planning / medidas de control |

· Carry out energy isolation of the installation. · Carry out the corresponding atmospheric measurements. · Personnel trained and authorised to enter Confined Space. · Have and disseminate the contingency/emergency plan. |

||

|

Work at height (When a tarea se realice a una altura a más de 1,80 mts con respecto al plano inferior). |

Example of activity s |

· Work on ramps, scaffolding, walkways. · Work on AIB reduction gearboxes that do not have a basket. · Work on repeater antennas. · Work on roofs and overhangs. |

|

|

Planning of the tasks / measures to be taken control |

· Identify which personal fall protection equipment to use and how to use it. · Check fall protection equipment before use. · Always be attached to an anchorage point. |

||

|

Electrical installations (applies to electrical installations carried out by our own and contracted personnel). |

Example of activities

|

Work without voltage Work with voltage in remote MV installations Work with voltage in contact MV installations. Work with voltage in LV. Work with safety voltage. |

|

|

|

Task scheduling / control measures |

Work without VOLTAGE by applying THE 5 GOLDEN RULES. Visibly isolate the installation. Lock the necessary cutting and sectioning devices in the open position using danger/lockout/safety padlock cards. Check that there is no voltage in each phase using the appropriate equipment. Install grounding and short-circuit systems at all points where voltage may be present. Delimit the work area or zone. |

Work with voltage applying the 5 golden rules. Verify that personnel are qualified for TCT. Verify work methods in associated instructions. Check the certifications of gloves, sleeves, sheaths, blankets, hydro-lifts with baskets, and other regulatory elements in force. Use the PPE required for these tasks: Dielectric helmet with chin strap, insulated footwear, eye protection. Insulated gloves suitable for the voltage of the installation. Insulated maneuvering poles, voltage detectors or testers. |

|

|

|

Once the work has been completed, the person responsible for the work, the person responsible for the deconsignation is carried out by the. |

|

|

Excavation |

Example of actividades |

· Excavation/trenching deeper than 1,20 mt. · Excavations/trenches where interference is suspected or known to exist. · Scarification work. |

|

|

Planning of tasks / measures for control |

· Confirm that potential interferences have been identified. · Determine the type and number of escape routes. · Mark and delimit the work area. · Verify that ground movement is being properly managed to avoid cave-ins. · Dispose of the removed soil at a distance from the edge of the excavation. · When the excavation is more than 1,80 m deep, a safety harness and lifeline must be provided. · Implement protection methods for the entry of personnel into excavations and trenches. |

||

|

|

|

Slope/perimeter slope of the excavation at 30°. |

|

|

|

Slope / Perimeter slope of the excavation 45°. |

||

|

|

Slope / partial slope of the excavation. |

||

|

|

Slope / partial slope of the excavation. |

||

|

|

Shoring / shoring of the excavation. |

||

|

Hot and cold |

Example of activities |

Cold · Work requiring insulation, lockout/tagout and not covered by other permits (work on satellites, aqueducts, pipelines). · Work on tanks not requiring confined space permits. · Work on lifting equipment and materials in batteries, plants or other service installations outside the classified area. |

|

|

Hot Tasks that may produce a heat source (a flame, spark or other ignition source) capable of igniting flammable vapours, gases or dust and solid fuels, papers, in the following installations: · Treatment or storage facility and batteries. · Oil pipelines and/or collectors, aqueducts and/or recovery water satellites. · Gas installations: gas well pipelines, gas pipelines, gas compressor or regulating plant, gas heaters |

|||

|

Task planning / control measures |

· Ensure the energy isolation of the installation to be intervened. · Evaluate the placement of protective screens where there could be potential for fire or explosion, due to the projection of particles, electric arc flames, etc. (tasks close to dry topsoil). · The presence of flammable gases and explosive atmospheres must be determined by using the appropriate detector. · Notify the supervisor if you suspect the presence of gas, if you notice combustible or toxic material near the work area |

||

Exposure

In all processes in various operational areas there is the presence of chemicals from the extraction of hydrocarbons.

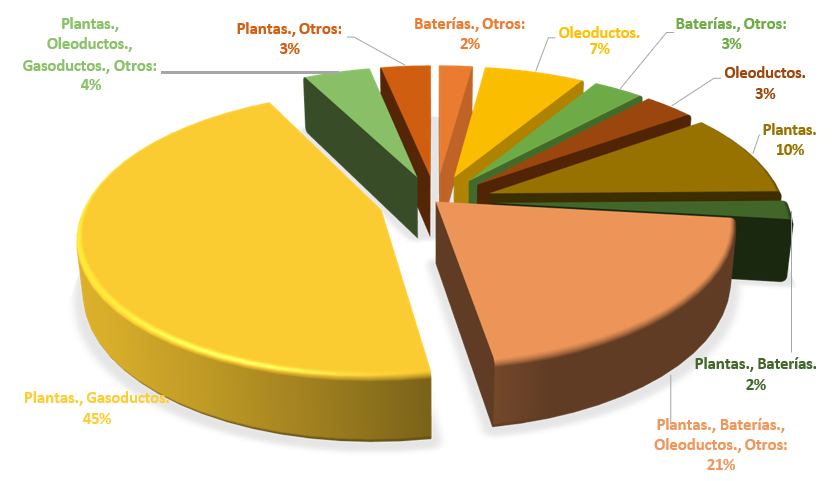

Figure 20. Areas where chemicals are present

Areas where the person has knowledge of the presence of chemicals.

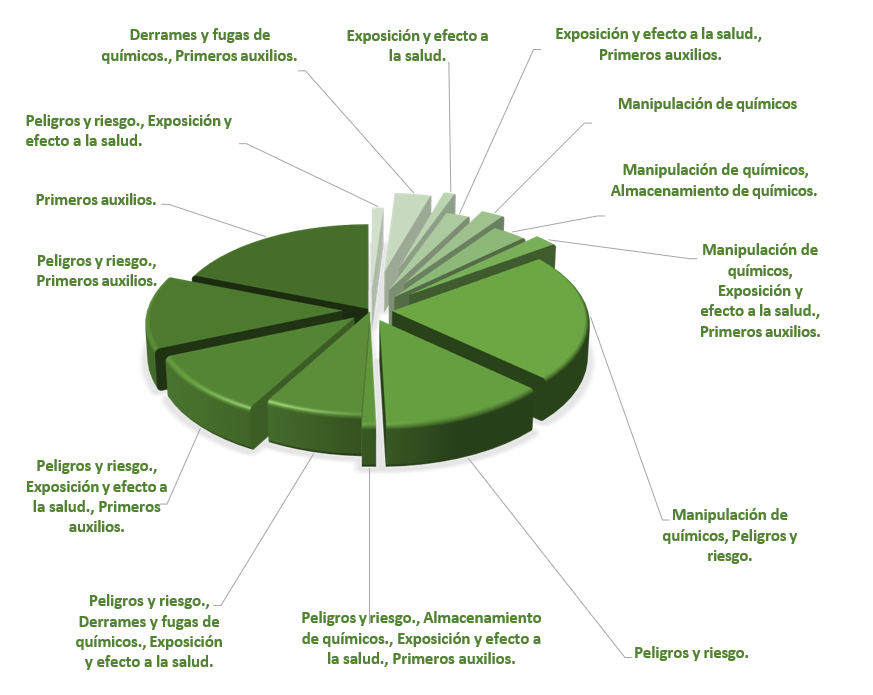

Figure 21. Hazard exposures

Hazards that the person who is exposed on a daily basis in the workplace believes he/she is exposed to.

Figure 22. Daily exposure to hazards

Dangers that are exposed on a daily basis in the activity carried out by the operative in the workstations performing the different tasks.

Figure 23. Chemical exposure

|

Table 2. Level of knowledge of hazards and exposures when handling chemicals |

|

|

Inhalation of gases from the decomposition of organic matter. |

Fossil fuels come from living organisms, resulting from the transformation of organic matter, initially by bacterial action, and then by transformations due to the increase of temperature by burial together with sediments, in sedimentary basins. Gases from crude oil extraction, sulphur, hydrogen sulphide H2S. hydrogen sulphide H2S. |

|

Handling of chemicals. |

Crude oil and its derivatives, e.g. paraffin, water, heavy oils, paraffins and asphalts. Lubricating chemicals for petroleum. |

|

Inhalation of chemical chemicals. |

Soot is the result of incomplete combustion of hydrocarbons. hydrocarbons. Example: chimneys. |

|

Others. |

Solid and liquid airborne particles suspended in air, complex mixtures containing, inter alia, dust, pollen, soot, smoke and small liquid droplets. suspended in the air, complex mixtures containing, among other things, dust, pollen, soot, smoke and small liquid droplets. |

Figure 24. Characteristics of H2S

H2S can be perceived even at low concentrations, it has particular characteristics.

Figure 25. Tasks with more exposure to chemicals

In the development of these works, different tasks are carried out under various environmental conditions.

The fluid produced by the wells, whether it is gas, oil, or water, arrives via pipelines to enter the battery.

Process control flow chart

Figure 26. Process control flow chart

Figure 27. Effects where an exhibition has been presented

Symptoms associated with the presence of H2S.

Figure 28. H2S emission sources

Hydrogen sulphide occurs both naturally and as a product of human activities.

Figure 29. Effect of H2S on metals

All small concentrations of H2S can or do strongly accelerate the corrosion of metals.

Figure 30. Gas Detector

H2S is highly flammable, explosive, and extremely toxic. To accurately monitor all areas where this gas may pose a risk, a variety of gas detectors are available to detect H2S, including personal multi-gas detectors and single-gas monitors.

Figure 31. Places where H2S is found

H2S occurs naturally in crude oil, natural gas, volcanic gases, and hot springs. It can also be produced as a result of bacterial degradation of organic matter.

Figure 32. Pipe materials that do not corrode with H2S Hydrogen Sulphide acid

Documentation

To carry out work in various areas and processes within deposits, a series of documentation must be complied with by applicable laws, decrees, resolutions, standards, operational work procedures, and work permits that have been authorized to perform the tasks.

Figure 33. Cassifications and knowledge of documents

For the activity they carry out, there is a document that establishes the safety standards to carry out these activities safely.

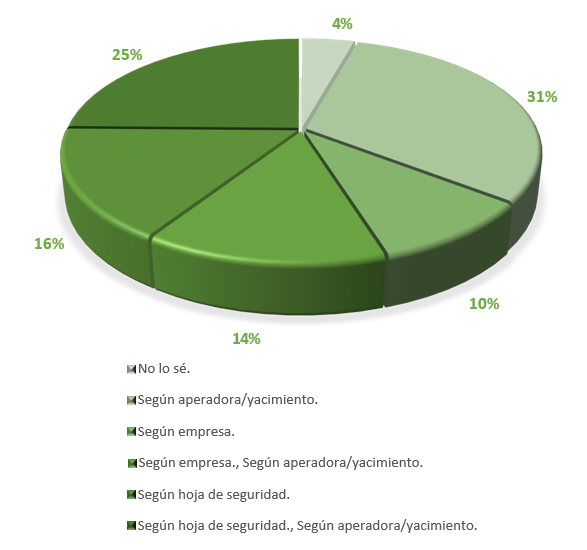

Figure 34. Documentation for chemical handling

The company and its operators have a document that establishes and outlines the activities to be carried out for the handling of chemicals; however, there is a lack of knowledge and training among operating personnel.

Attached as an Annex is a risk analysis of different tasks, safety sheets, and operating procedures.

Figure 35. Accessible documentation

Operational personnel have access to the documentation enabling them to carry out the work, operating procedures, risk analysis, safety data sheets and work permits.

Figure 36. Staff training

With the data obtained from the surveys, we observe the training topics that the operational staff receive in the field, meeting rooms, or canteens, which they are exposed to daily during their activities.

Figure 37. Work permits

Work permits must be signed by authorising personnel, area personnel and the person performing the task.

Figure 38. How to act

In the event of contact with chemical products, proceed as indicated in the GHS product safety sheet. After first action on site, proceed to role activation.

Figure 39. Emergency roles

Each operator and company has its designated emergency roles, which apply to any event, regardless of its nature.

Relation to Personal Protective Equipment and Training.

Depending on the exposure, the amount of gas in the air, and the type of work, employees are required to wear different levels of PPE.

Figure 40. Personal protective equipment

The companies provide you with the appropriate personal protective equipment for the tasks by means of job planning and risk analysis.

Figure 41. Personal protective equipment for work with chemicals

It is observed that personnel lack knowledge of the appropriate PPE for tasks. Supervisors and middle management ensure that all work is carried out and chemical products are handled using the proper PPE.

Personal protective equipment (PPE) for the different exposures.

These correspond to any equipment, apparatus, or device specially designed and manufactured to protect the body from damage caused by accidents at work or occupational diseases and must be provided after an analysis of the work or planned work to be carried out. The characteristics and/or data sheets of these devices are attached as an appendix.

Figure 42. PPE Selection Matrix for Different Occupational Hazards

DISCUSSION

In this scientific manuscript, we wanted to show the working conditions of 3 (three) companies working in 3 (three) oilfields located in the Province of Chubut, Comodoro Rivadavia City, the dangers that workers are exposed to in different areas, sectors, and the exposure to H2S Hydrogen Sulphide Gas or Hydrogen Sulphide Gas in the work they carry out in their professions.(23,24,25)

No information was found in the SRT sources regarding the risks and dangers in the oil activity in terms of H2S exposures, intoxications, occupational diseases, accidents, and/or fatalities in the different activities in oilfields in the Argentine Republic, nor information from official published statistics, only the answers of the survey participants were analyzed, comparing the level of knowledge of personal dangers with the occurrence of situations of exposure to H2S.(26,27,28)

From the health system, the danger that workers face when exposed to hydrogen sulfide gas, which is highly toxic and causes numerous accidents, is clearly expressed, not only in open work areas but also in areas of natural accumulation. This is why it is necessary to have atmosphere monitoring systems, as well as portable, fixed, and wireless gas detectors and breathing equipment (such as self-contained breathing apparatus, masks, cartridge chambers, and air supplies) to protect workers when necessary.(29,30,31)

According to the risks and operational and waste management controls for H2S in the facilities, some adverse situations may occur, including explosions, uncontrolled fires, spills, and environmental contamination.(32,33,34) It is, therefore, essential to consider that in any risk analysis, worst-case scenarios and protective measures are taken into account.(35,36,37) This creates logistics not only in terms of safety measures but also in terms of reaction measures for these scenarios since a material such as H2S, which is not only toxic but also flammable and explosive, necessitates minimizing risks.(38,39,40)

The installation of specialized equipment is vital to mitigate or resolve possible scenarios in an emergency beyond the control of the facility's security forces. Contained Breathing Apparatus (SCBA), or Breathing Apparatus), designed and developed to supply breathable air in atmospheres immediately hazardous to health and life.(41,42)

During the leak, H2S can mix with water or other liquid elements and become soluble, causing a reaction that creates toxic liquid elements. These elements, when present in high concentrations, become very dangerous. Therefore, body protection is required to contain the spill and prevent it from reaching other operating parts.(43,44,45)

But it must also be considered that in these concentrations, H2S could cause an uncontrolled fire or, in the worst case, a sudden and violent explosion. It would be worth considering more drastic measures in the event of a fire. As a self-igniting element, the burning of this gas could take several hours; a typical fire-fighting device with a duration of 60 minutes may be insufficient. In this case, closed-circuit equipment may be an option, as these devices provide breathable air for more than 4 hours.(46,47)

For personnel inside a confined facility, such as a platform where escape is impossible, who must wait for emergency responders to arrive, they should be sheltered from a fire or explosion in specially designed spaces that can withstand extreme conditions and provide life support until evacuation personnel enter the platform.(48,49,50)

Figure 43. Operator leaving a confined space wearing respiratory protection

By having the support of safety equipment for daily use or specialized solutions, as well as training and education for its personnel, to protect the most important thing: their lives.(51,52)

To carry out their activities, companies must comply with the management systems of the operators, which provide them with the required working conditions, including operations, work permits, and authorizations. This ensures compliance with procedures to maintain the safety of operations and facilities, as well as the physical integrity of workers.(53,54,55)

As a result of the analysis of the workstations and the execution of the tasks, the lack of information and training of the operative personnel and middle management concerning this was corroborated:(56,57,58)

· Drafting of work permits to carry out the tasks; this affects both the applicant and the person enabling the work (operating personnel) and the executor (the person in charge of the crew who signs the WP).

· The presence of H2S in areas and work sectors where tasks are frequent and daily, whether in production processes or civil works and piping.

· The absence of atmospheric gas detectors at the work fronts, especially in classified areas, either due to lack of equipment or lack of knowledge that atmospheric measurements should be carried out. The effect of toxic gases, the atmospheric environment where an individual may be, depends on the time they are exposed to the gas as well as the concentration of the gas; adverse effects are generated in the organism, irritating the soft tissues of the body, such as the eyes, nose, throat, and lungs. High concentrations quickly dampen the sense of smell, and continuous exposure can cause asthma attacks, respiratory distress, unconsciousness, and death.

· The daily exposure of personnel in different areas is high, as all tasks carried out in the oilfields involve the presence of H2S from the venting of any hydrocarbon-conducting installations. Attached as an annex is the gas measurement protocol provided by the operator to enable tasks in areas classified as plants or batteries.

The presence of risk analysis for tasks at the work fronts, along with the corresponding permit, is also observed. When speaking with and questioning the crew, they indicate a lack of knowledge regarding the risk analysis, including how to interpret it, the steps involved, hazards, severity, probability, and countermeasures to be taken.(59,60,61)

The operating procedures for all tasks in the surveyed companies are not available,(62,63,64) nor are the safety sheets. It should be noted that the operating personnel state that they do not have the documentation in physical form, which they must request from their supervisor, who provides it to them.(65,66)

The Company and Operator Policies are mandatory corporate policies, and non-compliance with them is strictly enforced for all personnel.(67,68,69)

The Personal Protective Equipment (PPE) provided by the companies is sufficient for the tasks that the personnel perform. Still, it was observed in the field that the operational personnel do not take care of them, nor do they carry out maintenance or keep them in a place where they are not exposed to deterioration. It is necessary to conduct investigations, field visits, and audits of work fronts to engage more with the operational personnel, as it is evident that there is a lack of training, awareness, planning, hazard identification, risk assessment, and unsafe work environments, and to determine the safety measures to prevent accidents. Records of audits and field visits are attached as annexes.(70)

It should be noted that it is advisable to train all workers on the characteristics, properties, and risks of H2S, to inform on the use of personal protective equipment, first aid, and emergency and rescue plans, applying safe work rules and procedures, complying with existing legal provisions in this respect and, last but not least, first aid practices and rescue and evacuation drills for the injured or intoxicated.

The collection of data that exists to date is fundamental when it comes to assessing the risks of an activity that has been carried out for years, in different ways, at various scales, and is not given the importance it deserves in the work context. However, the totality of the evaluation of exposure to H2S is still far from providing solutions. This work is a contribution to this and future research and not the only definitive measure to eradicate the risk; in the annexes, Work Permits establish the minimum mandatory conditions for the control of work with significant risks through the implementation of written documents and a methodology called to improve the management of Operational Safety which is notoriously what is not reflected in practice.

CONCLUSIONS

In conclusion, the conditions to which workers are exposed in the oil industry are not adequate. The presence of H₂S, the characteristics of the atmospheric environment, the working environment, inherent hazards, risks, and the lack of preventive or mitigation measures, as well as poor training of operating personnel in various areas, represent serious deficiencies. In addition, atmospheric gas measurement equipment and their respective certifications are not systematized in the companies' operating procedures.

This final work has been highly enriching, as it has allowed us to understand the diverse realities of the oil industry and to integrate multiple areas of knowledge, all of which are interconnected with other practices and tasks within the sector. At the same time, it was possible to deal directly with technical content on a highly relevant and topical subject, such as risk analysis at the worksite, actively involving all members of the crews.

Finally, it is encouraging to think that this work may serve as a contribution to future academic research, the development of protocols, or at least as a basis for further study of a little-known topic that has been the subject of study in different parts of the world for some time.

BIBLIOGRAPHIC REFERENCES

1. Ley N° 17.319. Ley de Hidrocarburos. 1967. http://servicios.infoleg.gob.ar/infolegInternet/anexos/15000-19999/16078/norma.htm

2. Ley N° 19.587. Ley de Higiene y Seguridad en el Trabajo. 1972. http://servicios.infoleg.gob.ar/infolegInternet/anexos/15000-19999/17612/norma.htm

3. Ley N° 24.557. Ley de Riesgos del Trabajo. 1995. http://servicios.infoleg.gob.ar/infolegInternet/anexos/25000-29999/27971/texact.htm

4. Ley N° 25.675. Ley General del Ambiente. 2002. http://www.opds.gba.gov.ar/sites/default/files/LEY%2025675.pdf

5. Ley N° 26.773. Régimen de Ordenamiento de la Reparación de los Daños Derivados de los Accidentes de Trabajo y Enfermedades Profesionales. 2012. http://servicios.infoleg.gob.ar/infolegInternet/anexos/200000-204999/203798/norma.htm

6. Decreto N° 658. Riesgos del Trabajo. 1996. http://servicios.infoleg.gob.ar/infolegInternet/anexos/35000-39999/37572/texact.htm

7. Decreto N° 911. Higiene y Seguridad en el Trabajo. Reglamento para la Industria de la Construcción. 1996. http://servicios.infoleg.gob.ar/infolegInternet/anexos/35000-39999/38568/texact.htm

8. Decreto N° 1338. Servicios de Medicina, Higiene y Seguridad en el Trabajo. 1996. http://www.siape.gba.gov.ar/rrhh/images/nacionales/DECRETO%201338%201996.pdf

9. Decreto N° 658. Relevamiento de Agentes de Riesgo y Enfermedades Profesionales. Declaración Jurada ART. 1996. http://servicios.infoleg.gob.ar/infolegInternet/anexos/35000-39999/37572/texact.htm

10. Decreto N° 658. Listado de Enfermedades Profesionales. 1996. https://www.argentina.gob.ar/normativa/nacional/decreto-658-1996-37572/normas-modifican

11. Decreto N° 49. Listado de Enfermedades Profesionales. 2014. http://servicios.infoleg.gob.ar/infolegInternet/anexos/225000-229999/225309/norma.htm

120. Resolución SRT N° 463/2002. Listado de Sustancias y Agentes Cancerígenos. http://upcndigital.org/~legislacion/CYMAT/Riesgos%20de%20Trabajo/2009-Resolucion%20SRT%200463_textact.pdf

0

13. Resolución SRT N° 743/2003. Sustancias Químicas a Declarar. http://servicios.infoleg.gob.ar/infolegInternet/anexos/90000-94999/90519/norma.htm

14. Resolución SRT N° 299/2011. Registro y Provisión de Elementos de Protección Personal (EPP). http://servicios.infoleg.gob.ar/infolegInternet/anexos/180000-184999/180669/norma.htm

15. Resolución SRT N° 441/1991. Contaminantes Químicos. https://www.argentina.gob.ar/normativa/nacional/resoluci%C3%B3n-441-1991-24543

16. Resolución SRT N° 953/2010. Espacios Confinados. https://www.ecofield.net/Legales/LRT/res953-10_SRT.htm

17. Resolución SRT N° 415/2002. Listado de Sustancias y Agentes Cancerígenos. http://servicios.infoleg.gob.ar/infolegInternet/anexos/75000-79999/79053/texact.htm

18. Resolución N° 310/03. Modificación del listado mezclas y explosivos. http://servicios.infoleg.gob.ar/infolegInternet/anexos/75000-79999/79053/texact.htm

19. Resolución N° 37/2010. Exámenes médicos. https://www.argentina.gob.ar/normativa/nacional/resoluci%C3%B3n-37-2010-163171

20. Resolución N° 23/2009. Condiciones básicas de higiene y seguridad. https://www.argentina.gob.ar/normativa/nacional/decreto-231-2009-151988/normas-modifican

21. Resolución N° 801/2015. Sistema Globalmente Armonizado de clasificación y etiquetado de productos químicos (SGA/GHS). http://servicios.infoleg.gob.ar/infolegInternet/verNorma.do?id=245850

22. Resolución N° 861/2015. Mediciones de contaminantes químicos. https://www.srt.gob.ar/wp-content/uploads/2014/03/images_pdf_Resolucion_861-15_Contaminantes_quimicos.pdf

23. Resolución N° 861/2015. Protocolo para medición de contaminantes químicos en el aire de un ambiente de trabajo. https://www.srt.gob.ar/wp-content/uploads/2014/03/images_pdf_Resolucion_861-15_Contaminantes_quimicos.pdf

24. Norma IRAM 3625. Espacios confinados. 2003. https://higieneyseguridadlaboralcvs.files.wordpress.com/2012/07/iram3625-espacios-confinados.pdf

25. Norma IRAM 3801. Sistemas de gestión de seguridad y salud ocupacional. 1998. https://www.magyp.gob.ar/sitio/areas/d_recursos_humanos/concurso/normativa/_archivos//000007_Otras%20normativas%20especificas/000000_NORMA%20IRAM%203800.pdf

26. Norma ISO 45001. Sistemas de gestión de salud y seguridad en el trabajo. Reemplaza a OHSAS 18001. 2018. https://www.diba.cat/documents/467843/172263104/GUIA_IMPLEMENTACION_ISO45001.pdf

27. Norma ISO 9001. Sistemas de gestión de la calidad. 2015. http://www.itvalledelguadiana.edu.mx/ftp/Normas%20ISO/ISO%209001-2015%20Sistemas%20de%20Gesti%C3%B3n%20de%20la%20Calidad.pdf

28. Norma ISO 14001. Sistemas de gestión medioambiental. 1996. http://www.itvalledelguadiana.edu.mx/ftp/Normas%20ISO/ISO%2014001-2015%20Sistemas%20de%20Gestion%20Mabiental.pdf

29. Ministerio de Desarrollo Productivo. Hidrocarburos. https://www.argentina.gob.ar/eiti/hidrocarburos

30. Ministerio de Empleo y Seguridad Social. Convenio Colectivo de Trabajo. Sindicato del Petróleo y Gas Privado del Chubut. 2010. https://petroleroschubut.com/pdf/1_convenio_colectivo.pdf

31. Superintendencia de Riesgos del Trabajo (SRT). Manual de Buenas Prácticas – Industria Petrolera. 2016. https://www.srt.gob.ar/wp-content/uploads/2016/08/MBP-.-Industria-Petrolera.pdf

32. Agencia para el Registro de Sustancias Tóxicas y Enfermedades. https://www.atsdr.cdc.gov/es/phs/es_phs114.html

33. Gobierno de Navarra. Manuales de buenas prácticas ambientales: Soldadura. https://www.uis.edu.co/webUIS/es/gestionAmbiental/documentos/manuales/Buenas%20Practicas%20Ambientales%20-%20Soldadura.pdf

34. Instituto Argentino del Petróleo y del Gas (IAPG). Aspectos técnicos, económicos y estratégicos de la exploración y producción de hidrocarburos. 2012. https://www.iapg.org.ar/web_iapg/publicaciones/libros-de-interes-general/exploracion-y-produccion-de-hidrocarburos

35. Asociación Chilena de Seguridad (ACHS). Medidas preventivas ante emanaciones de ácido sulfhídrico. https://www.achs.cl/portal/trabajadores/Capacitacion/CentrodeFichas/Documents_pdf/medidas-preventivas-ante-emanaciones-de-acido-sulfhidrico.pdf

36. Wang R. La función dual del sulfuro de hidrógeno. Investigación y Ciencia. 2010. https://es.wikipedia.org/wiki/%C3%81cido_sulfh%C3%ADdrico

37. Air Liquide. Hoja de datos de seguridad del producto: Sulfuro de hidrógeno. 2014. https://industrial.airliquide.com.mx/sites/industry_mx/files/sds/2018/07/12/alm-022_sulfuro_de_hidrogeno_rev_03.pdf

38. YPF. Hoja de datos de seguridad del producto: Mezcla propano – propileno. 2013. https://edicion.ypf.com/productosyservicios/Descargas/FDS-Propano-Propileno.pdf

39. Mercuria. Hoja de datos de seguridad del producto: Petróleo crudo. 2017. https://www.mercuria.com/sites/default/files/ES_SDS_Crude_SDS%20SGS%20GHS%20%28Reach%20ANNEXII%29_2015211_MERCURIA-370_0.pdf

40. Libus. Elemento de protección personal: Casco. https://www.libus.com.ar/casco-libus-proseg--det--890011

41. Libus. Máscaras respiratorias. https://www.libus.com.ar/mascaras-de-proteccion-respiratoria-proteccion-respiratoria-libus--prod--5

42. Libus. Protección ocular. https://www.libus.com.ar/protecciOn-ocular--prod--3

43. Sebastián Boris. Elemento de protección personal: Proveedor. https://www.sebastianboris.com.ar/

44. Boris Hnos. Elemento de protección personal: Proveedor. https://www.borishnos.com.ar/inicio

45. Drägerwerk. H2S: Un reto creciente en la industria del gas y el petróleo. 2010. https://www.draeger.com/library/content/h2s-e-book-9072501-es.pdf

46. Petroquimex. H2S en la industria petrolera. 2014. https://petroquimex.com/h2s-en-la-industria-petrolera/

47. Vidal S. Procedimiento corporativo: permisos de trabajos. C-S-PO-01. 2018.

48. Díaz J. Listado de trabajos que requieren la emisión de un PT. C-S-RO 01.00.01. 2016.

49. Rodríguez S. Instructivo permiso de trabajo en caliente y frío. C-S-ITO 01.01. 2019.

50. Rojas J. Instructivo permiso de trabajo en espacios confinados. C-S-ITO 01.02. 2019.

51. Quesada I. Instructivo permiso de trabajo en altura. C-S-ITO 01.03. 2019.

52. Ulloa G. Instructivo permiso de trabajos en instalaciones eléctricas. C-S-ITO 01.04. 2018.

53. Díaz J. Instructivo permiso de trabajos de excavación. C-S-ITO 01.05. 2018.

54. Cantasano P. Sistema de permisos de trabajo. YFP-505-NO032-LG-AR. 2012.

55. YPF. Permiso de trabajo frío-caliente. RG01.

56. YPF. Permiso de trabajo en excavación. RG02.

57. YPF. Permiso de trabajo en altura. RG03.

58. YPF. Permiso de trabajo eléctrico. RG04.

59. YPF. Permiso de trabajo para espacios confinados. RG05.

60. YPF. Pruebas adicionales de gas. RG06.

61. YPF. Bloqueo mecánico y etiquetado. RG07.

62. Formica D. Procedimiento estándar: sistema de permisos de trabajos. PAE-PE01. 2011.

63. PAE. Formulario: permiso de trabajo frío/caliente.

64. PAE. Certificado: trabajo en altura.

65. PAE. Certificado: confirmación de aislamiento de energía.

66. PAE. Certificado: espacios confinados.

67. PAE. Certificado: excavaciones.

68. PAE. Registro: medición de atmósfera.

69. Martínez P. Ingeniería en producción petróleo y gas. Comodoro Rivadavia, Chubut: Universidad Nacional de la Patagonia San Juan Bosco; 2012.

70. Marchioro Klimczyk E. Tecnicatura en petróleo y gas. Comodoro Rivadavia, Chubut: Instituto Superior de Educación Tecnológica CeRET-Chubut; 2016.

FINANCING

None.

CONFLICT OF INTEREST

The authors declare that there is no conflict of interest.

AUTHORSHIP CONTRIBUTION

Conceptualisation: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Data curation: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Formal analysis: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Research: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Methodology: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Project management: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Resources: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Software: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Supervision: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Validation: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Visualisation: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Writing - original draft: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.

Writing - proofreading and editing: Agostina Constansa Rodriguez, Hernan Carlos Hoyos.